The NEU Nanofiber Electrospinning Unit uses electrospinning techniques to safely and easily produce nanofibers with diameters of 50 to 800 nm. This device is widely used in the automotive industry for research and development of filters and fuel cells.

The NEU Nanofiber Electrospinning Unit is capable of producing 50 to 800 nm diameter fibers. The device’s biggest feature is the ability to produce nanofibers easily from a small amount of various polymers using an electrospinning technique. Currently, use of nanofibers in raw materials, IT, biotechnology, and healthcare industries is expected to increase dramatically as manufacturers look to take advantage of increased surface area and finer fiber materials.

Yoshihiro Yamashita,

Associate Professor at Osaka Seikei College

(present: Professor at the Research Center for Fibers and Materials, University of Fukui)

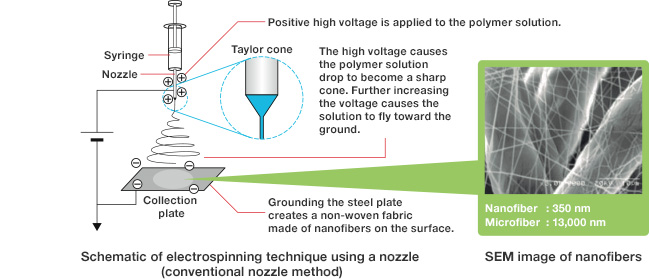

As shown in the diagram, the electrospinning device consists of a pointed positive electrode (capillary) and a flat negative (ground) electrode. High voltage is applied between the two electrodes, and the charged molten polymer or polymer solution coming from the capillary is attracted through the electric field toward the negative electrode. At this point, polymers with low molecular cohesion become a spray, and those with high molecular cohesion are further separated into fibers that are attracted to the negative electrode, where they form a thin layer of fibers.

| Model, Product Name |

NEU Nanofiber Electrospinning Unit |

| Dimensions (W × D × H) *approx. | 900 × 750 × 1080 mm (Including pilot lamp) |

| Weight *approx. | 120 kg |

| Power supply, Frequency | 100VAC, 50/60Hz |