"Texture" has long been referred to as the material texture and tactile sensation - what people feel when they touch an object.

The "Criteria of quality evaluation" is based on the subtle differences which artisans and experts with long experience can distinguish, is only subjective from hand touch sensation.

It is difficult for people without experience to determine this.

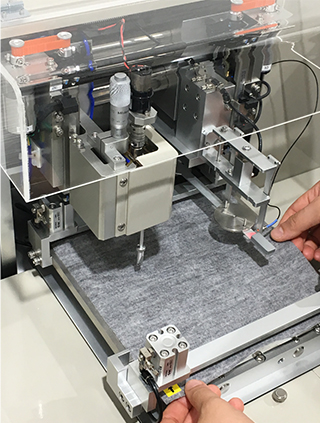

Hand movements such as "stroke", "stretch", "bend", "finger push" are used when people distinguish texture. KES testers can reproduce those movements and sensitivity, and generate measurement data.

Using this data, human subjective evaluation can be converted into an objective evaluation which can be shared by everyone.

This is the technology of Texture Measurement.

Our technology makes it possible to pursue comfort and to make the artisans expertises available to everyone.

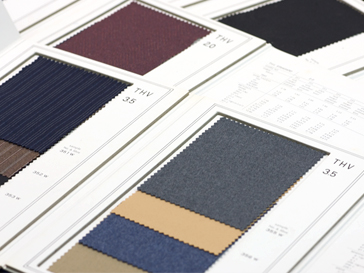

In the late 1960s, Dr. Sueo Kawabata from the Faculty of Engineering at Kyoto University collaborated with KATO TECH to develop a prototype texture measurement tester. This tester was utilized by the Fabric Texture Measurement and Standardization Research Committee to measure the texture of 710 types of fabrics. Through applied research by Dr. Kawabata and Dr. Masako Niwa from the Faculty of Human Life and Environment at Nara Women's University, subjective assessments of texture by fingers and hands were successfully transformed into objective data. This technology, known as KES (KAWABATA EVALUATION SYSTEM), is commonly referred to as "KES" in the industry.

"KES" was originally developed for textile measurement, however it has now been utilized in various industries as this technology has wider applications.

"Food texture", "Ease of carrying a container", "Cosmetic application comfort", "Interior surface comfort" and

"Coating smooth texture".

The technology of texture measurement is used in various industries from the environment to human welfare.

With a focus on people, its applications will advance to other areas in future,