1949 |

The Beginning of Kato Iron Works - From Materials Store to the Manufacturing IndustryKato Iron Works was established in 1949 to sell leftover materials from the war.

At the time of Kato Iron Works |

1964 |

We manufacturedIn 1964, we cooperated in the manufacture of the medals used in the Tokyo Olympic Games. The Olympic committee presented us with replicas of the silver and bronze medals.

Replicas of Tokyo Olympic Games medals Collaboration with Dr. Sueo Kawabata of the Faculty of Engineering at Kyoto University.Dr. Sueo Kawabata of Kyoto University, who started the study of textile texture, enquired about the skilled craftmanship necessary to produce "a bending spacer" for physical property evaluation. Turning Point: Desire To Produce Testers That Can Evaluate Physical PropertiesCollaboration with Dr. Kawabata continued and Kato Tech proceeded to "manufacture new products".

The 1st Model of KES-F2 Pure Bending Tester

The 1st Model of KES-F4 Surface Tester |

1970- |

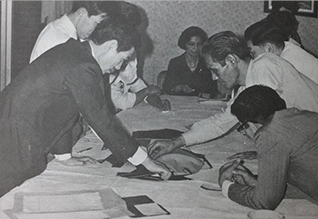

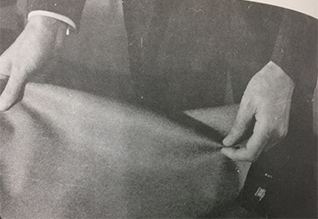

The Birth of KESIn 1970, with an increasing need for objective texture evaluation technology, "The Hand Evaluation and Standardization Committee (HESC)" was set up in The Textile Machinery Society of Japan. Its purpose was the "standardization of the hand evaluation of fabrics" and the "analysis of hand judgement which had been done by the experts in the factories in Japan". At that time, Dr. Kawabata and Dr. Masako Niwa of Nara Women's University played a central role in this committee. Skilled engineers from Japan's leading textile companies and university researchers were members of this committee. The committee took three years to evaluate approx. 500 different types of fabrics and defined "primary hand expressions" and "total hand value", and successfully developed an " objective evaluation method for fabric texture". The KES measurement conditions do not conform to JIS and ISO standards, however they are recognized and used worldwide by many skilled technicians and researchers in universities and companies. *Reference:

The Hand Evaluation and Standardization Committee*

Typical hand movement of Japanese experts for texture evaluation*

Standard reference materials for texture |

Present |

The Founder's Principles Will Be Passed Down To The FutureSince we were established, we have continued to manufacture and sell various instruments while keeping our policy of "make it as good as possible".

|

1961 |

Kato Tech Co., Ltd. Established |

1972 |

Successfully commercialization of F-Type measurement instrument with fabric and yarn texture measurement technology (KES). |

1973 |

KES-YN1 commercialized |

1978 |

4 models of KES-FB series commercialized |

1984 |

KES-F7 commercialized |

1985 |

BX5450 commercialized |

1986 |

KES-SE commercialized |

1987 |

KES-F8 commercialized |

1991 |

KES-FB1-A commercialized |

1991 |

The head office and factory was newly built |

1992 |

KES-FB2-A commercialized |

1994 |

KES-FB3-A commercialized |

1996 |

KES-FB4-A commercialized |

2002 |

FR07 commercialized |

2003 |

KDMD commercialized |

2005 |

HFT03C commercialized |

2007 |

KK01 commercialized |

2007 |

Shanghai representative office established |

2010 |

AwardTRI Princeton "Best Paper Award" |

2011 |

HapLog commercialized |

2013 |

AwardThe Society of Instrument and Control Engineers "System Integraion Award for Technical Achievement" |

2016 |

AwardKYOTO Industrial Support Organization 21 "the Special Technical Achievement Award 2016 of Kyoto Small and Medium Enterprises" |

2018 |

Showroom was newly built |

2019 |

KES-QM commercialized |