The KK01 Scratch Tester uses a rigid pin to scratch such targets as film, plastic, automotive interior and exterior material, and coating material to evaluate the target’s scratch resistance (scratch characteristics).

*conforming to ASTM: D7027-05 and ISO: 19252

Standardized increased load scratch testing can be conducted in accordance with ASTM and ISO guidelines.

This testing allows for the utilization of coating material research and flaw occurrence mechanism analysis, enabling quantitative assessment of scratch characteristics.

• KK01: Configurable load 1 to 200 N

This device is capable of calculating scratch coefficient of friction, a physical quantity directly related to surface damage.

This feature can be used to perform initial configured testing and ultimate load indentation testing. Performing these tests prior to actual testing allows the load range to be set quickly.

Even for samples with an uneven surface that make scratch evaluation difficult, such as textured surfaces, this feature makes testing possible without compromising linear load increase capabilities.

To handle a wide variety of evaluations with varying types of damage (gloss scratches, scaling, cutting damage, etc.), Kato Tech offers a variety of tips in addition to the standard ⌀1mm tip. Kato Tech also offers tip customization to fit customer testing requirements.

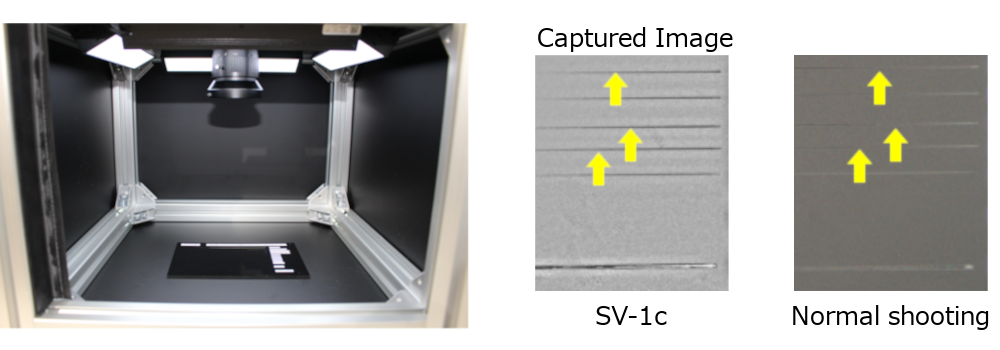

AI camera to image “scratch resistance (scratch characteristics) ”. Accurate detection of scratches even with dirt or oil on them. Evaluation of hard-to-see flaws can measure. In addition to scratching with a scratch tester, more accurate testing can be done by imaging the scratch resistance.

Click here for product information

| Model, Product Name |

KK01 Scratch Tester |

| Dimensions (W × D × H) *approx. | 965 × 530 × 690 mm |

| Weight *approx. | 150 kg |

| Power supply, Frequency | 100VAC, 50/60Hz |

| Interface | PC (included) |

| OS | Windows 7/8/10 |

| Sample size | 200 × 420 mm (max.) Thickness: 5 mm (max.) |

| *Configurable load 1 to 200 N |